- All Products

- All Products

- DCEF-Sound Insulated (Exterior Mounting type Centrifugal Fan)

DCEF-Sound Insulated (Exterior Mounting type Centrifugal Fan)

http://www.dwellventilation.com/shop/dcef-sound-insulated-exterior-mounting-type-centrifugal-fan-2699 http://www.dwellventilation.com/web/image/product.template/2699/image_1920?unique=765126aDCEF Exterior Wall-Mounted Centrifugal Fan – High-Performance Outdoor Ventilation

- Premium-grade weatherproof fan designed for reliable outdoor wall installation

- Enhanced motor quality for superior performance, longevity, and quiet operation

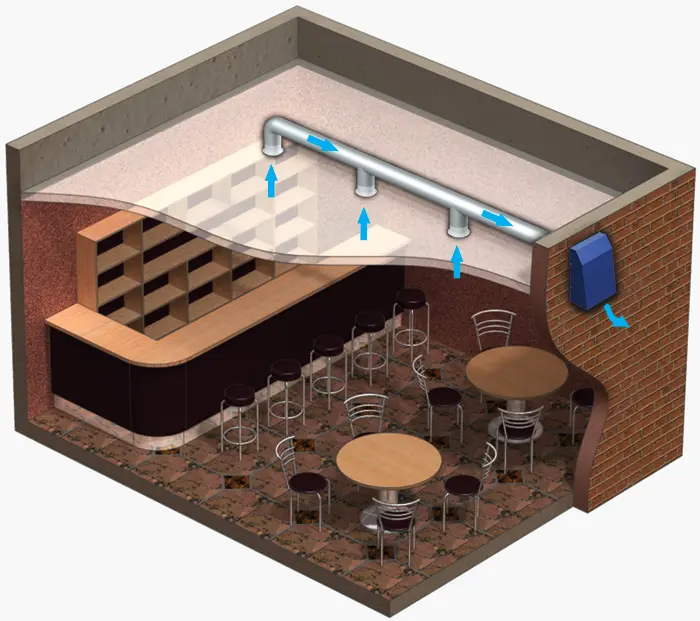

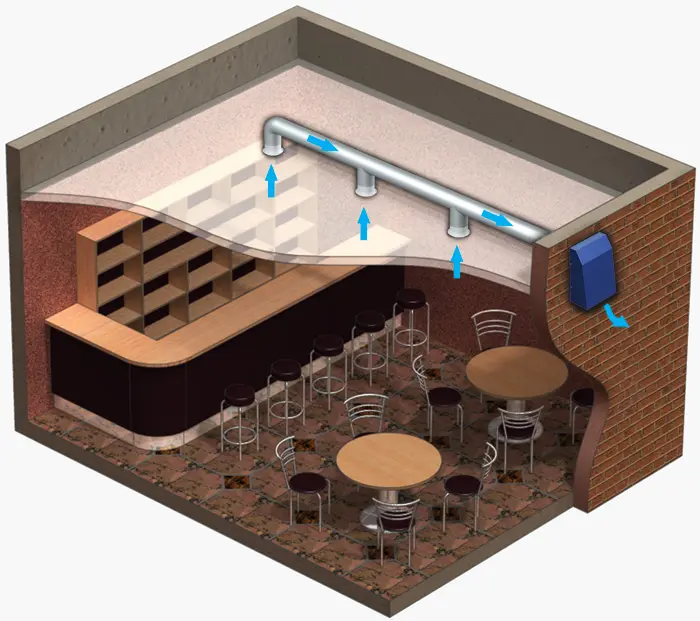

- Ideal for continuous air extraction from kitchens, bathrooms, and humid areas

- Vertical air discharge prevents wall staining and ensures clean airflow

- Protective grill prevents entry of birds, insects, and debris

- Supports step or smooth speed control with compatible external controllers

- Easily mounts on exterior walls and connects to round ducting systems

A perfect upgrade for residential or commercial setups needing durable and efficient exhaust ventilation.

Application:

DCEF Exterior Wall-Mounted Centrifugal Fan – Powerful Extraction, Built for Outdoors

- Built with a robust, weather-resistant steel body for safe exterior installation

- Efficient centrifugal airflow with vertical discharge to prevent wall staining

- Quiet motor with thermal protection and long-life ball bearings (40,000+ hrs)

- Bird and rodent-proof grill ensures clean, uninterrupted operation

- Easily mounts to exterior walls and connects to round ducts

- Supports step or smooth speed control via external controller

Ideal for homes, kitchens, shops, or industrial setups needing reliable, space-saving exhaust.

Design

1. Steel casing with polymeric coating ensures motor protection against direct humidity exposure in case of the unit outdoor mounting.

2. The fan bottom has a bird and rodent proof guard.

3. Air is exhausted vertically down.

Mounting

1. The fan is designed for outdoor surface wall mounting and connection to round duct of the respective diameter.

2. The fan is powered through the external terminals.

3. Electric connection and mounting shall be performed in compliance with the manual and wiring diagram provided in unit operation manual.

Motor

1. The centrifugal impeller with backward curved blades is powered by the single-phase motor with external rotor and overheating protection with automatic restart.

2. The motor is equipped with ball bearings for long service life designed for at least 40 000 hours.

3. For precise features, safe operation and low noise, each turbine is dynamically balanced while assembly.

4. Motor protection rating IP 44.

Speed Control

1. Smooth or step speed control with a thyristor or autotransformer speed controller.

2. Several fans may be connected to one speed controller provided that the total power and operating current do not exceed the rated speed controller parameters.

DCEF | DCEF | DCEF | DCEF 150K | DCEF 200K | |

Power (W) | 58 | 60 | 100 | 100 | 104 |

Current (Amp.) | 0.26 | 0.27 | 0.43 | 0.43 | 0.45 |

Speed (RPM) | 2500 | 2500 | 2600 | 2600 | 2600 |

Noise (db) | 54 | 54 | 58 | 58 | 62 |

Max air Capacity (m3/h) | 280 | 390 | 600 | 600 | 720 |

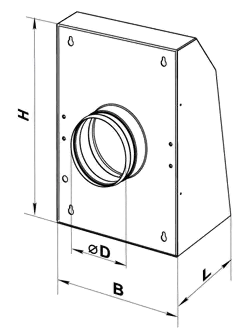

Parameter (mm) | DCEF 100 | DCEF 125 | DCEF 150 | DCEF 200 |

Ø D | 99 | 124 | 149 | 199 |

B | 260 | 260 | 300 | 300 |

H | 355 | 355 | 400 | 400 |

L | 138 | 138 | 138.2 | 138.2 |

File | Download/ |

Product Catalog DCEF PRO | |

Installation Manual DCEF PRO | |

CAD file for product | |

Product Images |

We’re here to help.

Contact our expert design team.

Contact Us

Start with the customer – find out what they want and give it to them.

Application

1. Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces.

2. Ventilation shaft mounting or duct connection.

3. Low to medium air flow motion for short distances at low air resistance.

4. Compatible with Ø 100-, 120-, 125- and 150-mm air ducts

Design

1. Modern design and aesthetic look.

2. The casing and the impeller are made of high-quality durable ABS plastic, UV resistant.

3. Various decorative plates for the front panel of the natural aluminum.

4. The intellectual impeller design makes the fan efficiency high and the service lifelong.

5. Protection rating IP34.

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer)

Motor

1. Reliable and low-watt electric motor.

2. Designed for continuous operation and requires no maintenance.

3. Equipped with overheating protection.

Speed Control

Manual:

1. The fan is controlled by a room light switch. It is not included in the delivery set.

2. The fan is controlled by the built-in pull cord switch V. Not applied in case of ceiling mounting.

3. Speed control is possible through a thyristor speed controller (see Electrical Accessories). Several fans may be connected to the same controller. Speed controllers can not be connected to the fans with Т, ТН, ТР, VТ, VТН modifications.

Automatic:

1. By the BU-1-60 electronic control unit. The control unit is supplied separately.

2. By the T timer (the built-in turn-off delay timer enables the fan operation within 2 to 30 minutes after the fan switching off).

3. By the humidity sensor and the TH timer (if the humidity level in the room exceeds the sensor threshold adjustable value within 60-90 % the fan switches automatically on and operates until the humidity level drops to the standard level, after that the fan continues operating within the time period according to the timer setting, then shuts down).

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Parameter | Value |

Ø D | 100mm |

B | 152mm |

H | 120mm |

L | 126mm |

L1 | 130mm |

Application

1. Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces.

2. Ventilation shaft mounting or duct connection.

3. Low to medium air flow motion for short distances at low air resistance.

4. Compatible with Ø 100-, 120-, 125- and 150-mm air ducts

Design

1. Modern design and aesthetic look.

2. The casing and the impeller are made of high-quality durable ABS plastic, UV resistant.

3. Various decorative plates for the front panel of the natural aluminum.

4. The intellectual impeller design makes the fan efficiency high and the service lifelong.

5. Protection rating IP34.

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer)

Motor

1. Reliable and low-watt electric motor.

2. Designed for continuous operation and requires no maintenance.

3. Equipped with overheating protection.

Speed Control

Manual:

1. The fan is controlled by a room light switch. It is not included in the delivery set.

2. The fan is controlled by the built-in pull cord switch V. Not applied in case of ceiling mounting.

3. Speed control is possible through a thyristor speed controller (see Electrical Accessories). Several fans may be connected to the same controller. Speed controllers can not be connected to the fans with Т, ТН, ТР, VТ, VТН modifications.

Automatic:

1. By the BU-1-60 electronic control unit. The control unit is supplied separately.

2. By the T timer (the built-in turn-off delay timer enables the fan operation within 2 to 30 minutes after the fan switching off).

3. By the humidity sensor and the TH timer (if the humidity level in the room exceeds the sensor threshold adjustable value within 60-90 % the fan switches automatically on and operates until the humidity level drops to the standard level, after that the fan continues operating within the time period according to the timer setting, then shuts down).

Start with the customer – find out what they want and give it to them.

Application

1. Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces.

2. Ventilation shaft mounting or duct connection.

3. Low to medium air flow motion for short distances at low air resistance.

4. Compatible with Ø 100-, 120-, 125- and 150-mm air ducts

Design

1. Modern design and aesthetic look.

2. The casing and the impeller are made of high-quality durable ABS plastic, UV resistant.

3. Various decorative plates for the front panel of the natural aluminum.

4. The intellectual impeller design makes the fan efficiency high and the service lifelong.

5. Protection rating IP34.

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer)

Motor

1. Reliable and low-watt electric motor.

2. Designed for continuous operation and requires no maintenance.

3. Equipped with overheating protection.

Speed Control

Manual:

1. The fan is controlled by a room light switch. It is not included in the delivery set.

2. The fan is controlled by the built-in pull cord switch V. Not applied in case of ceiling mounting.

3. Speed control is possible through a thyristor speed controller (see Electrical Accessories). Several fans may be connected to the same controller. Speed controllers can not be connected to the fans with Т, ТН, ТР, VТ, VТН modifications.

Automatic:

1. By the BU-1-60 electronic control unit. The control unit is supplied separately.

2. By the T timer (the built-in turn-off delay timer enables the fan operation within 2 to 30 minutes after the fan switching off).

3. By the humidity sensor and the TH timer (if the humidity level in the room exceeds the sensor threshold adjustable value within 60-90 % the fan switches automatically on and operates until the humidity level drops to the standard level, after that the fan continues operating within the time period according to the timer setting, then shuts down).

Start with the customer – find out what they want and give it to them.

%20(4%20Inch%20(100%20mm))?unique=765126a)

%20(4%20Inch%20(100%20mm))?unique=765126a)