- All Products

- All Products

- X200- 315 (Wall Axial Fan for Kitchen)

%20(8%20Inch%20(200%20mm))?unique=943db4c)

X200- 315 (Wall Axial Fan for Kitchen)

http://www.dwellventilation.com/shop/x200-315-wall-axial-fan-for-kitchen-2714 http://www.dwellventilation.com/web/image/product.template/2714/image_1920?unique=943db4c2. These fans can be used for the direct air exhaust or pressurization in smoke ventilation systems.

3. These fans are suitable for outdoor wall mounting.

Application

- Combined supply and exhaust ventilation systems for various premises where high air flow at relatively low system resistance is required.

- These fans can be used for the direct air exhaust or pressurization in smoke ventilation systems.

- These fans are suitable for outdoor wall mounting.

Product Specification:

| X 200 | X 315 |

Power | 55 | 145 |

Current (Amp.) | 0.26 | 0.66 |

Speed | 2300 | 2300 |

Noise (db) | 50 | 50 |

Max air Capacity (m3/h) | 860 | 2230 |

Design

1. The fan casing and the impeller are made of steel with polymeric coating.

2. x 200-315 fan terminal box is equipped with the cord for remote connection.

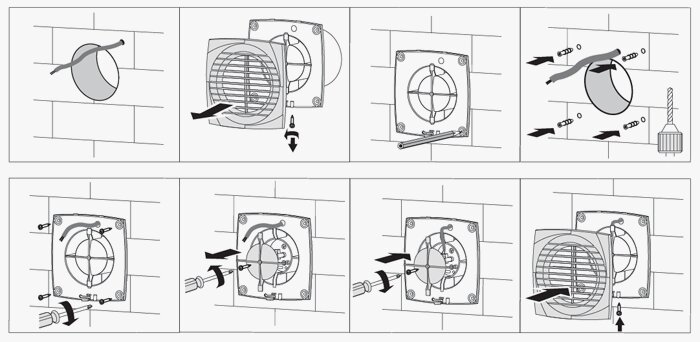

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer).

Motor

- The impellers are powered by two-, four- or six pole, single or three phase asynchronous motors with external rotor and built-in thermal overheating protection depending on the model.

- Ball bearings in the motor provide long service life designed for at least 40 000 hours.

- Motor protection rating IP44-IP54.

Speed Control

- Both smooth or step speed control is performed by means of the thyristor or autotransformer controller.

- Several fans can be connected to one controller if the total power and operating current do not exceed the rated controller values.

Parameter (mm) | X 200 |

Ø D | 210 |

Ø d | 7 |

B | 312 |

B1 | 260 |

L | 125 |

File | Download/ |

Product Catalog X200 - X315 | |

Installation Manual X200 - X315 | |

CAD file for product | |

Product Images |

We’re here to help.

Contact our expert design team.

Contact Us

Start with the customer – find out what they want and give it to them.

Application

1. Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces.

2. Ventilation shaft mounting or duct connection.

3. Low to medium air flow motion for short distances at low air resistance.

4. Compatible with Ø 100-, 120-, 125- and 150-mm air ducts

Design

1. Modern design and aesthetic look.

2. The casing and the impeller are made of high-quality durable ABS plastic, UV resistant.

3. Various decorative plates for the front panel of the natural aluminum.

4. The intellectual impeller design makes the fan efficiency high and the service lifelong.

5. Protection rating IP34.

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer)

Motor

1. Reliable and low-watt electric motor.

2. Designed for continuous operation and requires no maintenance.

3. Equipped with overheating protection.

Speed Control

Manual:

1. The fan is controlled by a room light switch. It is not included in the delivery set.

2. The fan is controlled by the built-in pull cord switch V. Not applied in case of ceiling mounting.

3. Speed control is possible through a thyristor speed controller (see Electrical Accessories). Several fans may be connected to the same controller. Speed controllers can not be connected to the fans with Т, ТН, ТР, VТ, VТН modifications.

Automatic:

1. By the BU-1-60 electronic control unit. The control unit is supplied separately.

2. By the T timer (the built-in turn-off delay timer enables the fan operation within 2 to 30 minutes after the fan switching off).

3. By the humidity sensor and the TH timer (if the humidity level in the room exceeds the sensor threshold adjustable value within 60-90 % the fan switches automatically on and operates until the humidity level drops to the standard level, after that the fan continues operating within the time period according to the timer setting, then shuts down).

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Parameter | Value |

Ø D | 100mm |

B | 152mm |

H | 120mm |

L | 126mm |

L1 | 130mm |

Application

1. Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces.

2. Ventilation shaft mounting or duct connection.

3. Low to medium air flow motion for short distances at low air resistance.

4. Compatible with Ø 100-, 120-, 125- and 150-mm air ducts

Design

1. Modern design and aesthetic look.

2. The casing and the impeller are made of high-quality durable ABS plastic, UV resistant.

3. Various decorative plates for the front panel of the natural aluminum.

4. The intellectual impeller design makes the fan efficiency high and the service lifelong.

5. Protection rating IP34.

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer)

Motor

1. Reliable and low-watt electric motor.

2. Designed for continuous operation and requires no maintenance.

3. Equipped with overheating protection.

Speed Control

Manual:

1. The fan is controlled by a room light switch. It is not included in the delivery set.

2. The fan is controlled by the built-in pull cord switch V. Not applied in case of ceiling mounting.

3. Speed control is possible through a thyristor speed controller (see Electrical Accessories). Several fans may be connected to the same controller. Speed controllers can not be connected to the fans with Т, ТН, ТР, VТ, VТН modifications.

Automatic:

1. By the BU-1-60 electronic control unit. The control unit is supplied separately.

2. By the T timer (the built-in turn-off delay timer enables the fan operation within 2 to 30 minutes after the fan switching off).

3. By the humidity sensor and the TH timer (if the humidity level in the room exceeds the sensor threshold adjustable value within 60-90 % the fan switches automatically on and operates until the humidity level drops to the standard level, after that the fan continues operating within the time period according to the timer setting, then shuts down).

Start with the customer – find out what they want and give it to them.

Application

1. Continuous or periodic exhaust ventilation of bathroom, showers, kitchens and other utility spaces.

2. Ventilation shaft mounting or duct connection.

3. Low to medium air flow motion for short distances at low air resistance.

4. Compatible with Ø 100-, 120-, 125- and 150-mm air ducts

Design

1. Modern design and aesthetic look.

2. The casing and the impeller are made of high-quality durable ABS plastic, UV resistant.

3. Various decorative plates for the front panel of the natural aluminum.

4. The intellectual impeller design makes the fan efficiency high and the service lifelong.

5. Protection rating IP34.

Mounting

1. The fan is mounted directly into the ventilation shaft.

2. In case of remote location of the ventilation shaft flexible air ducts may be used. The air duct is connected to the fan exhaust flange through a clamp.

3. Fixed to the wall by means of screws.

4. Suitable for ceiling mounting.

5. To connect a fan with a 12 V low voltage motor to 220 V/50 Hz power mains, it is necessary to purchase a step-down transformer (e.g. the TRF 220/12-25 transformer)

Motor

1. Reliable and low-watt electric motor.

2. Designed for continuous operation and requires no maintenance.

3. Equipped with overheating protection.

Speed Control

Manual:

1. The fan is controlled by a room light switch. It is not included in the delivery set.

2. The fan is controlled by the built-in pull cord switch V. Not applied in case of ceiling mounting.

3. Speed control is possible through a thyristor speed controller (see Electrical Accessories). Several fans may be connected to the same controller. Speed controllers can not be connected to the fans with Т, ТН, ТР, VТ, VТН modifications.

Automatic:

1. By the BU-1-60 electronic control unit. The control unit is supplied separately.

2. By the T timer (the built-in turn-off delay timer enables the fan operation within 2 to 30 minutes after the fan switching off).

3. By the humidity sensor and the TH timer (if the humidity level in the room exceeds the sensor threshold adjustable value within 60-90 % the fan switches automatically on and operates until the humidity level drops to the standard level, after that the fan continues operating within the time period according to the timer setting, then shuts down).

Start with the customer – find out what they want and give it to them.